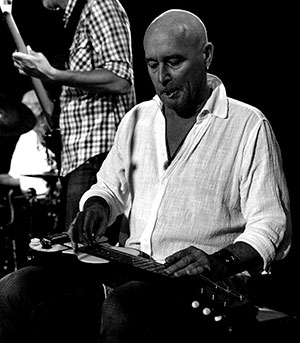

c. 1940 Rickenbacher Model B lap steel

This one was bought from Elderly Instruments in Lansing, Michigan USA in January 2020. I had been pining for the 1946 Rickenbacher that I had to sell a few years earlier for financial reasons.

The photo on the right is from their web site, prior to me fixing it up. This is the condition in which I bought it - "as is." It was a bit of a bargain because one of the cover plates was missing and another was broken but the electronics worked, the chrome on the pickup horseshoe was just about perfect, and the bakelite body was in perfect condition, far better shape than the one I'd owned previously. It also has a very good solid case that appears to be original. However it needed quite a bit of work - see below.

Perfect unchipped bakelite

The model B was made from 1935 to 1955. This one appears to have been made between 1939 and 1945.

- It has plastic body plates indicating it was made from 1938 onwards1.

- It has 2 control knobs on the treble side indicating it was made from 1939 onwards1.

- It has a 1½” pickup and the small headstock logo plate typical of those prior to 19461.

Pre 1946 logo plate on headstock

In a 1949 music store catalogue they are listed at $95.16. This pickup design is known as the 'horse shoe' pickup. It has been widely copied, not only in its own day when Kay apparently copied the design, but Cole Clark also did one on its modern lap steels for a while until I believe they were forced to stop making them by Rickenbacker's lawyers.

1½” horse shoe pickup with unblemished chrome

Under each of the white plates on the body there is an empty chamber that no doubt contributes to the sound, but would also help to keep the weight down a bit. This is a very heavy instrument for its size.

Repairs

Body Plates

One plate was missing, one was broken in half and another had a crack in it because they were 80 year old plastic that had warped and become brittle. I went to a guy to enquire about 3D printing and it turned out that he made props and things for film and TV and used a huge variety of techniques to produce a result. He suggested that a better option would be to make them from scratch myself. He sold me some white perspex that he cut into "roughs" and I sanded them down and refined the shapes. They're far from perfect but from more than a metre or so away they look fantastic. He said that there was a high risk the perspex would shatter when drilling holes so I decided to simply glue them in place with PVA glue, which should come off with water if I ever get some original metal plates.

At this point the only original plate is the one with the knobs on it.

Original plastic plate

with volume and tone controls

Tuners

The tuners that were originally fitted to these were apparently pretty cheap and nasty, but the ones that a previous owner had fitted were virtually unusable. Unfortunately the posts and peghead holes were unusually narrow (5.5mm diameter) and it was impossible to find any replacements that size. The smallest I could find were 6mm (most are at least 6.3mm). My guitar repairer knew someone who had worked for Rickenbacker and had restored a bakelite Model B using Kluson tuners, and he was able to give plenty of advice. So the steps were:

- Remove the old tuners and fill the existing screw holes with epoxy (they were in the wrong place anyway).

- Use a "mop" to enlarge the peghead holes for the replacement tuners. Drilling would be too risky as the bakelite could shatter, so the idea is to use some dowel wrapped in sandpaper, attach that to an electric drill and gradually sand the inside of the peghead holes to make them bigger. Very time consuming.

- Allow the epoxy to fully harden (so the screws don't wander) then gradually drill new screw holes in the correct place for the new tuners (Gotoh brand copies of Klusons). He drilled three times from 1mm up to 2mm to avoid chipping the bakelite. Then tapping three times - to 10 mm depth - with lubrication to keep the tap from jamming or damaging the little threads.

- Lubricate the peghead holes with graphite to allow smooth operation.

The replacement tuners that were on it when I bought it

Halfway through the job

New tuners fitted

Volume Control

The volume knob was very stiff and had a very uneven response. Apparently the wiring was weird and did not conform to anything on Rickenbacker website schematics. Also the pot was 100k - much lower than normal. The volume pot was replaced and now works beautifully.

More Info

- 1Serial numbers and model info

- Early history of electric instruments and Rickenbacher

- Greg Cutshaw - Steel Guitar

- Brad's page of Steel

- String gauge guide

This is intended for pedal steel but is also useful for lap steels. - My string gauges

- Diamond Bottlenecks

Lead crystal custom-made slides that have an unbelievable tone. - Bakelite repairs and restoration

- Lap steel capos